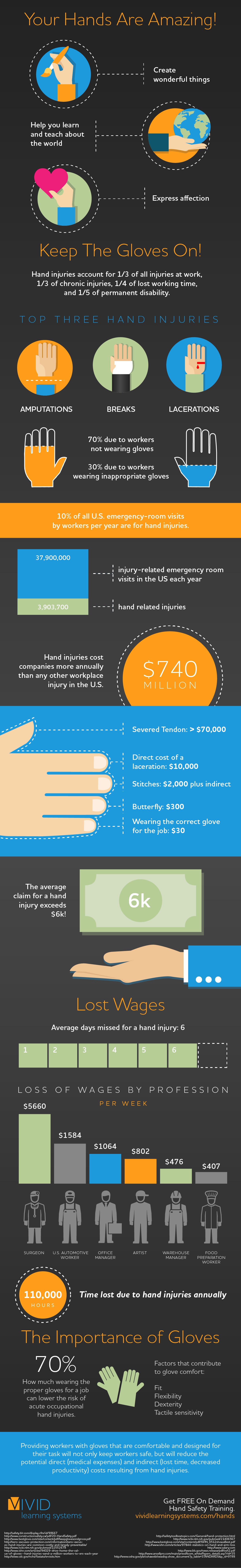

Occupational hand injuries account for more than one million emergency room visits per year. The first step in preventing hand injuries is to know the hazards involved in your job and how to avoid them.

Hand Safety

$24.15

Description

Learning Objectives

- Identify common hazards to the hands

- List methods and devices used to prevent hand injuries

- Describe the differences in hand protection devices (gloves)

Occupational hand injuries account for more than one million emergency room visits per year.

No matter what kind of work you do, you probably use many tools in your job. In many instances, your hands are the tools for the job and the rules you’d employ to take care of other tools also apply to your hands. For example, always use the correct tool for the job. It is “misuse” to use a tool for something other than it was intended. Never use your hands when another appropriate tool exists for the job.

The first step in preventing hand injuries is to know the hazards involved in your job and how to avoid them.

Injuries often occur because workers have bypassed or deactivated safety features on equipment. Perhaps they find it cumbersome, but guards and other safety features serve an important purpose—never tamper with them or modify controls that exist to protect you from specific injury, no matter how inconvenient these devices may appear.

Also, don’t remove personal protective equipment (PPE). For example, frostbite in the workplace often occurs because a worker removes his protective gloves in an extremely cold environment. Typically, he believes this will only be long enough to do some task that requires greater finger dexterity than can be accomplished with his gloves on, and this miscalculation creates serious risk.

Some injuries occur when employees choose not to follow process instructions. Often this is due to boredom with a routine task or the mistaken sense that the worker is experienced enough to bypass instructions.

In addition, distraction in the form of a wandering mind or wandering eyes can lead to injury. When working near hazards, you must always keep your mind on the task and your eyes on the job. Don’t rush and if you find yourself frustrated, stop and take a break. Frustration leads to carelessness and injury.

Finally, beware of thinking you can bend the rules “just this once.”

There are three types of safety controls your employer will use to help prevent hand injuries: engineering controls, administrative controls and personal protective equipment (PPE).

Engineering controls eliminate or effectively reduce hazards through safeguards built specifically to mitigate certain hazards, i.e., where equipment itself has built-in measures to protect the user. Engineering controls are always the preferred way to eliminate or reduce hazards, because the safety measure is built-in. They are the first line of defense. Engineering controls must be routinely calibrated and maintained to ensure they will work the way they are supposed to, every time.

Administrative controls are the procedures that you put in place to protect your workforce. While engineering controls are preferred, administrative controls are useful if engineering controls simply cannot be implemented, or when engineering controls alone cannot effectively reduce risk. Because administrative controls do not eliminate hazards, it is critical that employees follow the policies that safety professionals put in place. A good example is the adoption of a 100% glove use policy—gloves are to be used for all tasks.

Personal protective equipment is worn to minimize exposure to hazards when engineering and administrative controls are not feasible or are not sufficient to reduce hazards to acceptable levels. To protect hands from certain types of injury, gloves are the primary piece of PPE. PPE is considered the third line of defense, after engineering and administrative controls.

One of the most effective ways to protect your hands is to wear gloves when appropriate. In fact, according to the U.S. Bureau of Labor Statistics, 70% of workers who get hand injuries were not wearing gloves. The other 30%, who were wearing gloves, received their injury because their gloves were inadequate, damaged or were the wrong type of glove for the hazard.

Not all training is equal. With SafetyNow, learners and leaders will notice the difference in value:

- Quality: Professionally-researched and designed using the latest mobile and responsive technologies

- Convenience: Works instantly on any device, desktop or mobile

- Time savings: What learners need to know, not extra fluff or legalese

- Reporting: Consistent, instant compliance records available anytime

- Support: Customer and learner support included at no charge

- Any Learning Management System (LMS) Use with any SCORM, AICC, xAPI, TinCan, HTML5, or other LMS (learning management system).

- Any Device Desktop, laptop, tablet, or mobile phone – it simply works, everywhere.

- Engaging Professionally-developed, including an on-screen host and modern, easy-to-understand text, media, and voiceovers.

- Unlimited Attempts Each module can be taken as many times as required to get a passing grade. Unlike our competitor’s courses, if you get an answer wrong, you are redirected to the exact eLearning segment you struggled with… you don’t need to go through the entire module again, just the one part you need a refresher on.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.