-

Nuclear criticality accidents have killed, but these accidents don’t happen often because when they do occur, the results have historically proven disastrous; regulations, training, and procedural safeguards have all intensified in the wake of high-profile, fatal events around the world. Accidental criticality is a hazard unique to facilities where fissionable materials are handled or stored, such as nuclear fuel manufacturing and processing facilities. The Nuclear Regulatory Commission characterizes these events as “uncontrolled nuclear fission chain reactions.” So, that’s what we’re talking about, and unexpected, unplanned nuclear episode that poses risk to human health and wellbeing proportionate to the size of event and proximity of those exposed.

Nuclear criticality accidents have killed, but these accidents don’t happen often because when they do occur, the results have historically proven disastrous; regulations, training, and procedural safeguards have all intensified in the wake of high-profile, fatal events around the world. Accidental criticality is a hazard unique to facilities where fissionable materials are handled or stored, such as nuclear fuel manufacturing and processing facilities. The Nuclear Regulatory Commission characterizes these events as “uncontrolled nuclear fission chain reactions.” So, that’s what we’re talking about, and unexpected, unplanned nuclear episode that poses risk to human health and wellbeing proportionate to the size of event and proximity of those exposed. -

Fire extinguishers are one of the most reliable ways to put out fires in the workplace. Fire extinguishers are not a requirement, but if employers choose to provide them they must train workers in general fire extinguisher use to comply with OSHA standards. OSHA states that if employers expect workers to use the fire extinguishers themselves, hands-on training must be provided.

Fire extinguishers are one of the most reliable ways to put out fires in the workplace. Fire extinguishers are not a requirement, but if employers choose to provide them they must train workers in general fire extinguisher use to comply with OSHA standards. OSHA states that if employers expect workers to use the fire extinguishers themselves, hands-on training must be provided. -

Approximately 770 workers suffer face injuries on a yearly basis; most don't wear proper personal protective equipment (PPE) for face protection Proper personal protective equipment (PPE) is essential to any work environment for eye and face protection. The goal of this course is to show how to handle face and eye protection properly using personal protective equipment (PPE).

Approximately 770 workers suffer face injuries on a yearly basis; most don't wear proper personal protective equipment (PPE) for face protection Proper personal protective equipment (PPE) is essential to any work environment for eye and face protection. The goal of this course is to show how to handle face and eye protection properly using personal protective equipment (PPE). -

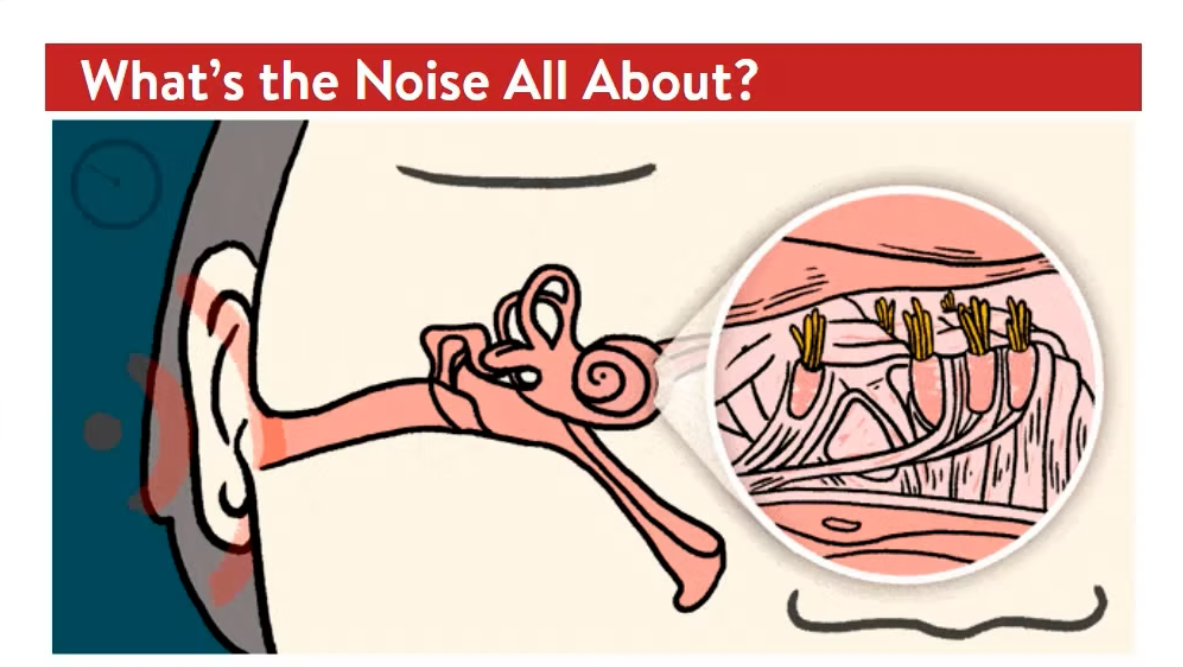

Can you put a price tag on the use of your hands? Some people don't realize the important of their hands until they aren't able to be used any longer. Hand injuries send a million workers to ERs each year, and hand injuries are the No. 2 leading cause of work-related injury and the most preventable through proper personal protective equipment (PPE).

Can you put a price tag on the use of your hands? Some people don't realize the important of their hands until they aren't able to be used any longer. Hand injuries send a million workers to ERs each year, and hand injuries are the No. 2 leading cause of work-related injury and the most preventable through proper personal protective equipment (PPE). -

Process safety management increases safety for the workforce. Now, small businesses with limited resources might use other ways to decrease the risks associated with hazardous chemicals in the workplace, but development of a process safety management program is the operating standard. An effective process safety management program requires employers to compile a written process information resource. This information enables workers to identify and understand the hazards posed by processes that involve highly hazardous chemicals.

Process safety management increases safety for the workforce. Now, small businesses with limited resources might use other ways to decrease the risks associated with hazardous chemicals in the workplace, but development of a process safety management program is the operating standard. An effective process safety management program requires employers to compile a written process information resource. This information enables workers to identify and understand the hazards posed by processes that involve highly hazardous chemicals.