-

Emergency planning is critical for operations that handle or produce significant quantities of hazardous materials. Because of the danger to employees working at these facilities and to the general public presented by the harmful release of hazardous materials, likes noxious, combustible gases and waste, people have a right to know about the potential for danger involved in related operations.

Emergency planning is critical for operations that handle or produce significant quantities of hazardous materials. Because of the danger to employees working at these facilities and to the general public presented by the harmful release of hazardous materials, likes noxious, combustible gases and waste, people have a right to know about the potential for danger involved in related operations. -

In this course you will learn how to identify how noise impacts hearing and the factors that determine the extent of hearing loss, identify noise exposure levels that require hearing protection according to Part VII of Canadian Regulations, identify how the types of hearing protectors are selected for a job, and their advantages and disadvantages for controlling noise exposure, identify correct use, care, and maintenance practices for hearing protectors and identify the requirements of a Hearing Conservation Program.

In this course you will learn how to identify how noise impacts hearing and the factors that determine the extent of hearing loss, identify noise exposure levels that require hearing protection according to Part VII of Canadian Regulations, identify how the types of hearing protectors are selected for a job, and their advantages and disadvantages for controlling noise exposure, identify correct use, care, and maintenance practices for hearing protectors and identify the requirements of a Hearing Conservation Program. -

In this course you’ll learn about the chemistry of Hydrogen Sulfide and how it is formed, the properties and characteristics of the gas, where Hydrogen Sulfide is likely to be located in your workplace, the potential health hazards of short term and long term H2S exposure, how to work safely with Hydrogen Sulfide and emergency response steps to take should you or a co-worker be exposed to this gas.

In this course you’ll learn about the chemistry of Hydrogen Sulfide and how it is formed, the properties and characteristics of the gas, where Hydrogen Sulfide is likely to be located in your workplace, the potential health hazards of short term and long term H2S exposure, how to work safely with Hydrogen Sulfide and emergency response steps to take should you or a co-worker be exposed to this gas. -

This lesson describes the importance of safety in the workplace and the employee’s role in maintaining a safe workplace. According to the National Federation of Independent Businesses defines ideal safety accountability as ideal accountability along with companies that strive for optimal safety performance display the highest level of organizational safety accountability.

This lesson describes the importance of safety in the workplace and the employee’s role in maintaining a safe workplace. According to the National Federation of Independent Businesses defines ideal safety accountability as ideal accountability along with companies that strive for optimal safety performance display the highest level of organizational safety accountability. -

The Occupational Safety and Health Administration (OSHA) has issued a final rule to curb lung cancer, silicosis, chronic obstructive pulmonary disease and kidney disease in America's workers by limiting their exposure to respirable crystalline silica. The rule is comprised of two standards, one for Construction and one for General Industry and Maritime. This lesson is designed to improve the safety of workers in environments where silica exposure hazards exist by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in the workplace.

The Occupational Safety and Health Administration (OSHA) has issued a final rule to curb lung cancer, silicosis, chronic obstructive pulmonary disease and kidney disease in America's workers by limiting their exposure to respirable crystalline silica. The rule is comprised of two standards, one for Construction and one for General Industry and Maritime. This lesson is designed to improve the safety of workers in environments where silica exposure hazards exist by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in the workplace. -

The purpose of the NFPA standard 70E is to provide a standard for safety-related work practices for the construction, maintenance, operation and demolition of electrical systems in the workplace. This Overview covers awareness-level information for workers who have jobs or assignments that bring them into contact with electrical hazards, such as arc flash and electric shock. Completing this lesson does not designate an employee as an electrically-qualified worker.

The purpose of the NFPA standard 70E is to provide a standard for safety-related work practices for the construction, maintenance, operation and demolition of electrical systems in the workplace. This Overview covers awareness-level information for workers who have jobs or assignments that bring them into contact with electrical hazards, such as arc flash and electric shock. Completing this lesson does not designate an employee as an electrically-qualified worker. -

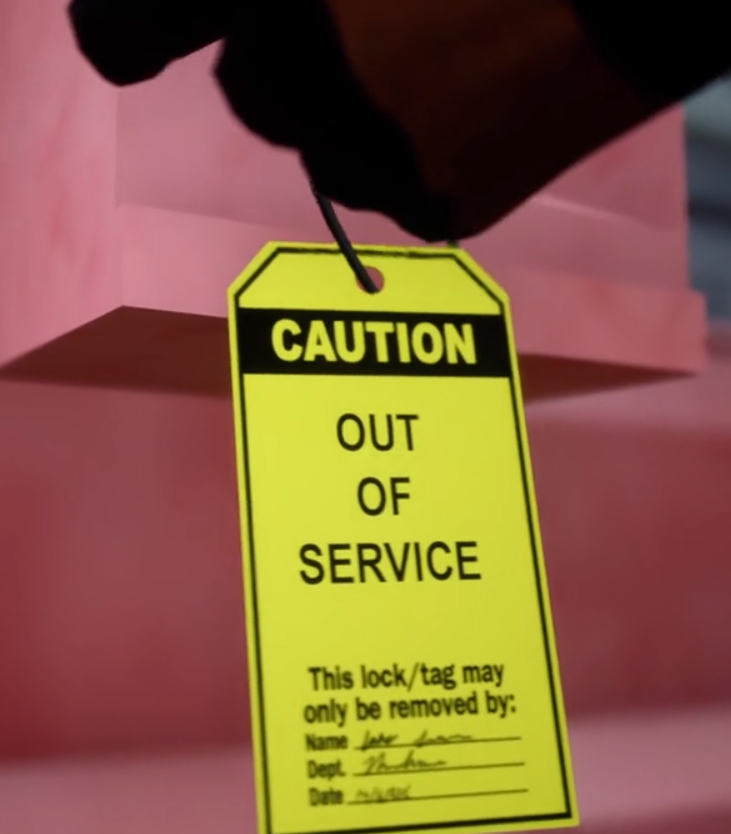

To protect you from the serious hazards posed by the unexpected start-up or operation of equipment during repair or maintenance, the Occupational Safety & Health Administration (OSHA) has established a Control of Hazardous Energy standard. It is commonly referred to as the lockout/tagout (LOTO), or energy isolation standard. This standard requires the application of markings and barriers that prevent unauthorized persons from energizing and operating equipment.Energy in any form becomes hazardous when it builds to a certain level or is released inadvertently or unexpectedly. Lockout/tagout refers to specific practices and procedures that safeguard employees from the unexpected startup of machinery and equipment, or the release of hazardous energy, during service or maintenance activities.

To protect you from the serious hazards posed by the unexpected start-up or operation of equipment during repair or maintenance, the Occupational Safety & Health Administration (OSHA) has established a Control of Hazardous Energy standard. It is commonly referred to as the lockout/tagout (LOTO), or energy isolation standard. This standard requires the application of markings and barriers that prevent unauthorized persons from energizing and operating equipment.Energy in any form becomes hazardous when it builds to a certain level or is released inadvertently or unexpectedly. Lockout/tagout refers to specific practices and procedures that safeguard employees from the unexpected startup of machinery and equipment, or the release of hazardous energy, during service or maintenance activities.