-

In this course you’ll learn about the chemistry of Hydrogen Sulfide and how it is formed, the properties and characteristics of the gas, where Hydrogen Sulfide is likely to be located in your workplace, the potential health hazards of short term and long term H2S exposure, how to work safely with Hydrogen Sulfide and emergency response steps to take should you or a co-worker be exposed to this gas.

In this course you’ll learn about the chemistry of Hydrogen Sulfide and how it is formed, the properties and characteristics of the gas, where Hydrogen Sulfide is likely to be located in your workplace, the potential health hazards of short term and long term H2S exposure, how to work safely with Hydrogen Sulfide and emergency response steps to take should you or a co-worker be exposed to this gas. -

As simple as using a ladder seems to be, the injury statistics indicate that it is one of the most abused tools we have. Accidents, particularly in the domestic setting, are frequently caused by overreaching or overextending from ladders to complete certain tasks, rather than doing the safe thing—climbing down and moving to a better access point. OSHA studies have shown that 100% of ladder related accidents could have been prevented using proper safety. The goal of this lesson is to provide awareness-level instruction on ladder hazards, safe use requirements, and best practices for all employees.

As simple as using a ladder seems to be, the injury statistics indicate that it is one of the most abused tools we have. Accidents, particularly in the domestic setting, are frequently caused by overreaching or overextending from ladders to complete certain tasks, rather than doing the safe thing—climbing down and moving to a better access point. OSHA studies have shown that 100% of ladder related accidents could have been prevented using proper safety. The goal of this lesson is to provide awareness-level instruction on ladder hazards, safe use requirements, and best practices for all employees. -

This Lock and Tag lesson creates awareness about the purpose of lock and tag procedures and employee roles and responsibilities related to lock and tag requirements. The lesson provides an overview of the hazards of uncontrolled energy sources and employer responsibilities and requirements for lock and tag. It also briefly outlines steps to protect workers.

This Lock and Tag lesson creates awareness about the purpose of lock and tag procedures and employee roles and responsibilities related to lock and tag requirements. The lesson provides an overview of the hazards of uncontrolled energy sources and employer responsibilities and requirements for lock and tag. It also briefly outlines steps to protect workers. -

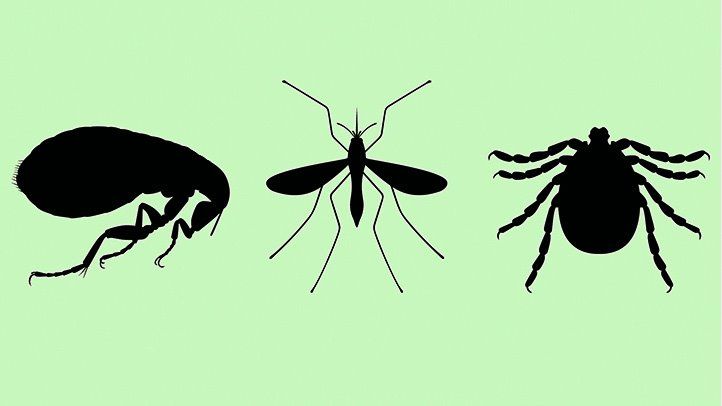

In this lesson, you will learn about the most-common vector-borne diseases and how you can avoid exposure and infection. You will learn general treatment guidelines; however, any treatment-related information provided in this lesson does not constitute medical advice and is not a substitute for evaluation by a qualified healthcare professional.

In this lesson, you will learn about the most-common vector-borne diseases and how you can avoid exposure and infection. You will learn general treatment guidelines; however, any treatment-related information provided in this lesson does not constitute medical advice and is not a substitute for evaluation by a qualified healthcare professional. -

The goal of the lesson is make employees aware of the primary objective of process safety management: to prevent unwanted releases of highly hazardous chemicals into locations that expose employees and others to serious hazards, and to provide an overview of the standards and best practices necessary to achieve that objective.

The goal of the lesson is make employees aware of the primary objective of process safety management: to prevent unwanted releases of highly hazardous chemicals into locations that expose employees and others to serious hazards, and to provide an overview of the standards and best practices necessary to achieve that objective. -

The goal of this lesson is to teach workers the purpose of respirators and the preparations, maintenance and storage requirements. Workers will also learn when it is permissible to leave a respirator use area, the warning signs that a respirator is not functioning properly, and how respirator emergencies and malfunctions should be handled.

The goal of this lesson is to teach workers the purpose of respirators and the preparations, maintenance and storage requirements. Workers will also learn when it is permissible to leave a respirator use area, the warning signs that a respirator is not functioning properly, and how respirator emergencies and malfunctions should be handled. -

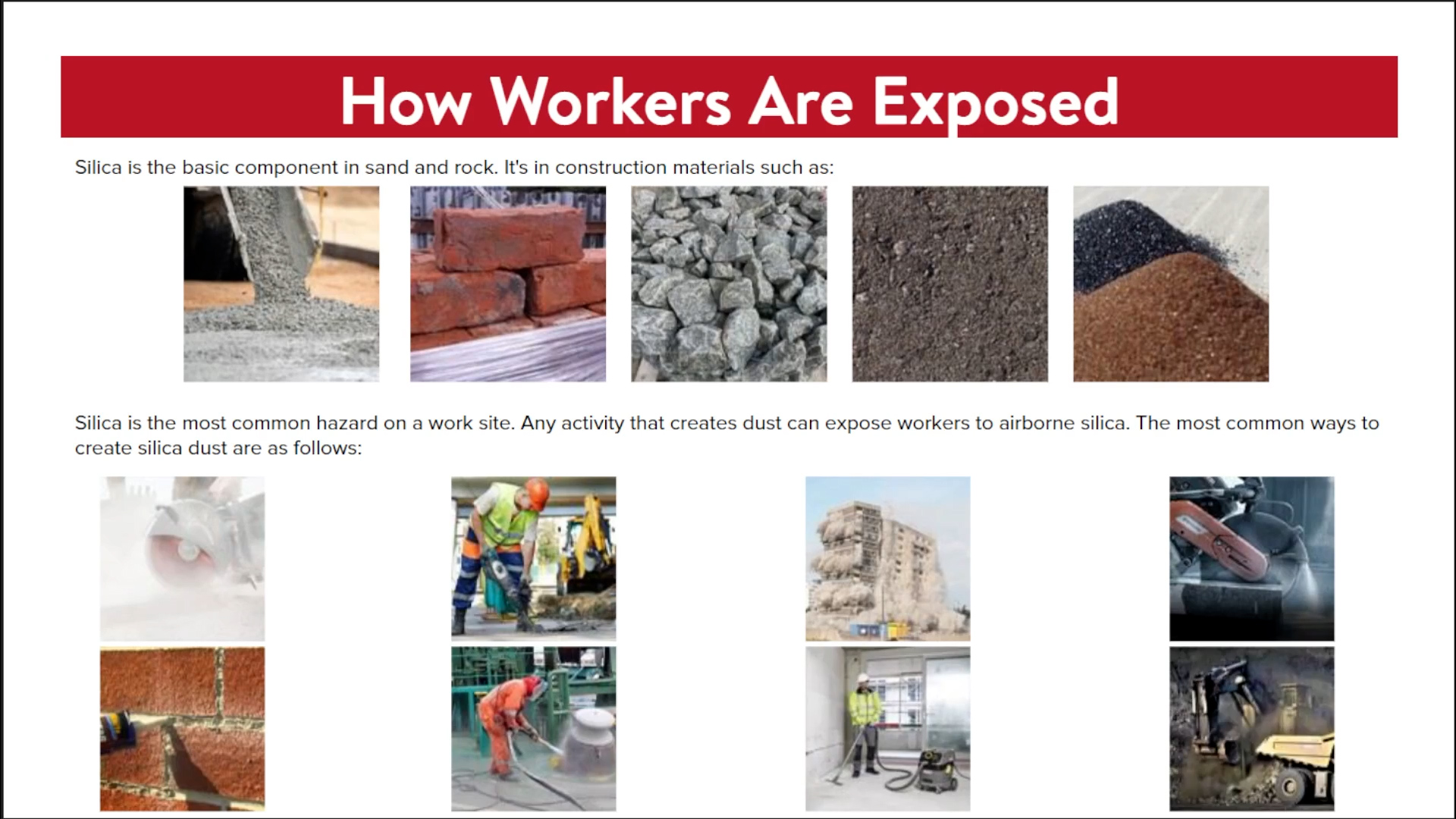

This lesson is designed as an intro/refresher to our Silica Hazards course in order to improve the safety of workers in environments where silica exposure hazards exist by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in the workplace.

This lesson is designed as an intro/refresher to our Silica Hazards course in order to improve the safety of workers in environments where silica exposure hazards exist by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in the workplace. -

Recent statistics from the Congressional Accountability Office of Compliance indicate that employee falls are private industry’s third leading cause of workplace fatalities. Around 600 workers die from a fatal slip, trip, or fall, each year. This overview of slips, trips, and falls helps reinforce good behaviors for workers on how and where to avoid areas where these hazards can reside.

Recent statistics from the Congressional Accountability Office of Compliance indicate that employee falls are private industry’s third leading cause of workplace fatalities. Around 600 workers die from a fatal slip, trip, or fall, each year. This overview of slips, trips, and falls helps reinforce good behaviors for workers on how and where to avoid areas where these hazards can reside. -

All employers covered by the Act are regulated by Part 1904 regulations. However, businesses with 10 or fewer employees and businesses with certain industry classifications are partially exempt from keeping OSHA injury and illness records, unless OSHA or the Bureau of Labor Statistics notifies them in writing that they must do so. All employers covered by OSHA—no matter the number of employees or industry classification—must report to OSHA any workplace incident that results in a fatality or the hospitalization of three or more employees.

All employers covered by the Act are regulated by Part 1904 regulations. However, businesses with 10 or fewer employees and businesses with certain industry classifications are partially exempt from keeping OSHA injury and illness records, unless OSHA or the Bureau of Labor Statistics notifies them in writing that they must do so. All employers covered by OSHA—no matter the number of employees or industry classification—must report to OSHA any workplace incident that results in a fatality or the hospitalization of three or more employees. -

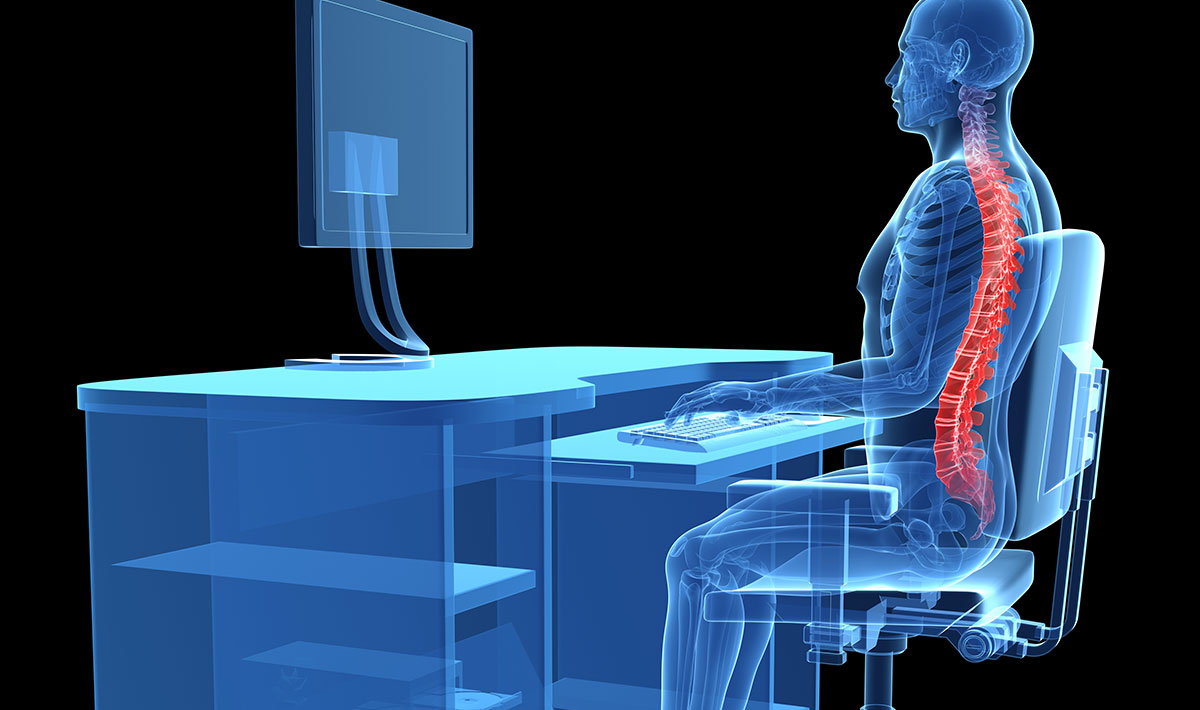

The purpose of this course is to recognize how practicing good posture while improving your work area conditions and working ergonomically will protect and strengthen your back. Learn how to identify how a healthy lifestyle, and improving your strength and flexibility, con protect you from work-related injuries.

The purpose of this course is to recognize how practicing good posture while improving your work area conditions and working ergonomically will protect and strengthen your back. Learn how to identify how a healthy lifestyle, and improving your strength and flexibility, con protect you from work-related injuries. -

Learning Objectives

- Describe the basic principle of hydraulics

- Explain the effect air can have on hydraulic systems

- Identify five components common to most hydraulic systems

- Describe two key considerations that must be taken into account when selecting a hydraulic pump

- Identify the two most common types of hydraulic circuits

-

This course will outline, in five steps, how health & safety awareness is imperative for worker safety. This course addresses safety and awareness in British Columbia by covering supervisor responsibilities, the rights of workers, understanding hazards in your workplace, getting help and being a role model.

This course will outline, in five steps, how health & safety awareness is imperative for worker safety. This course addresses safety and awareness in British Columbia by covering supervisor responsibilities, the rights of workers, understanding hazards in your workplace, getting help and being a role model. -

Sale!

Workers of all ages can be injured at work, but young and new workers may be more at risk. Injuries can result from inadequate training, orientation, and supervision; inexperience; and lack of awareness of workplace rights and responsibilities. This course will review risks , rights and responsibilities and refusing unsafe work.

Workers of all ages can be injured at work, but young and new workers may be more at risk. Injuries can result from inadequate training, orientation, and supervision; inexperience; and lack of awareness of workplace rights and responsibilities. This course will review risks , rights and responsibilities and refusing unsafe work. -

Sale!

Every federally regulated carrier and trucker must comply with the HOS rules. This course will cover what Hours of Service is, responsibilities, rules and requirements, off-duty information and regulations in Canada.

Every federally regulated carrier and trucker must comply with the HOS rules. This course will cover what Hours of Service is, responsibilities, rules and requirements, off-duty information and regulations in Canada. -

Sale!

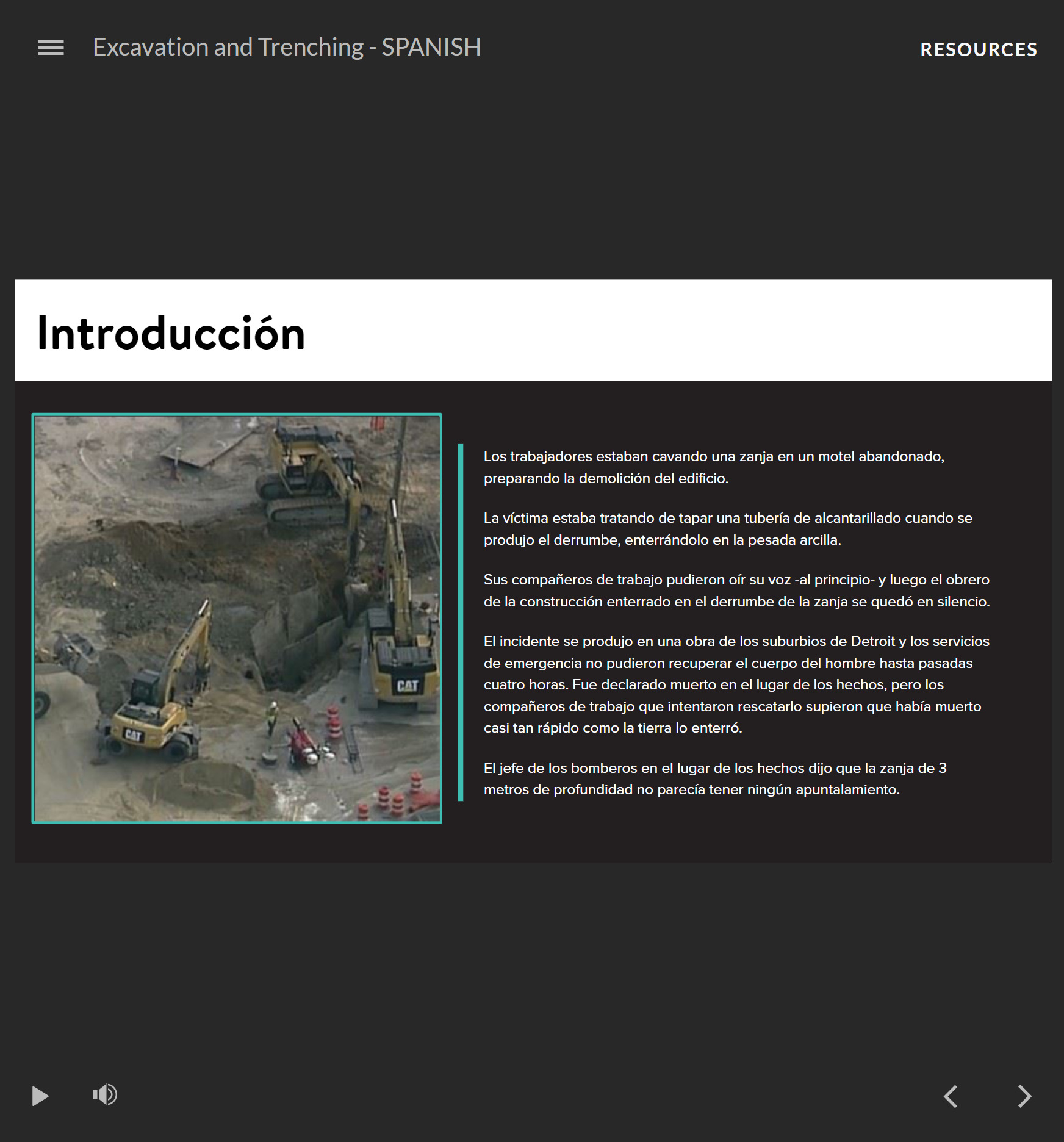

Los trabajos de excavación y zanjas matan a más de 50 trabajadores al año. Los empleados aprenderán a identificar los riesgos de excavación y zanja, las prácticas de trabajo seguras y los sistemas de protección, así como a recordar los requisitos de protección contra derrumbes diseñados para mantener a los trabajadores seguros.

Los trabajos de excavación y zanjas matan a más de 50 trabajadores al año. Los empleados aprenderán a identificar los riesgos de excavación y zanja, las prácticas de trabajo seguras y los sistemas de protección, así como a recordar los requisitos de protección contra derrumbes diseñados para mantener a los trabajadores seguros. -

Sale!

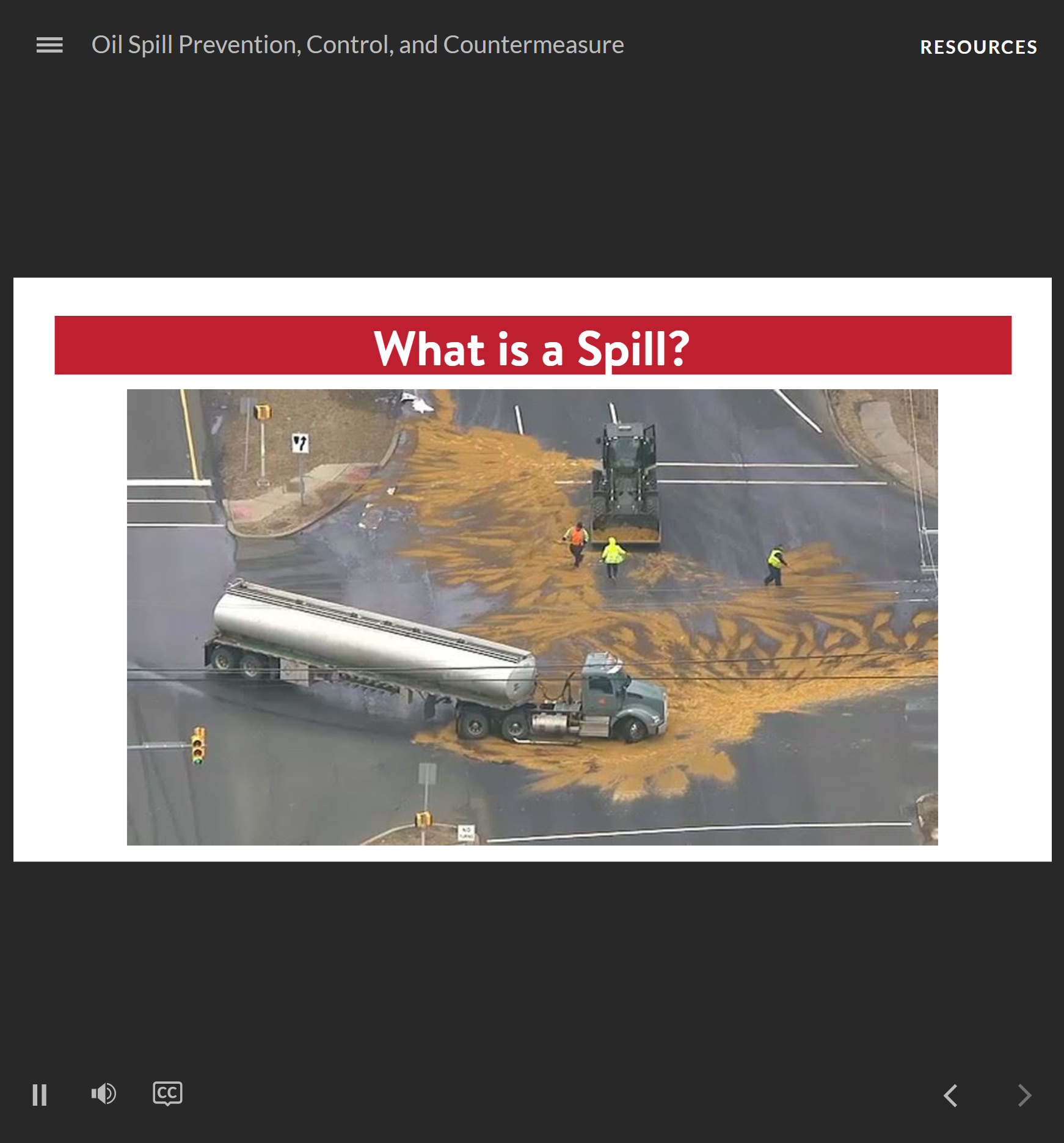

This course covers the harmful effects of spilled oil and regulations for oil pollution prevention. The purpose and requirements of a SPCC Plan, procedures to prevent spills, and measures for stopping a spill from reaching the environment.

This course covers the harmful effects of spilled oil and regulations for oil pollution prevention. The purpose and requirements of a SPCC Plan, procedures to prevent spills, and measures for stopping a spill from reaching the environment. -

Sale!

The course covers workplace eye hazards, PPE used to protect against them, and proper fit and care of PPE.

The course covers workplace eye hazards, PPE used to protect against them, and proper fit and care of PPE. -

Common hazards associated with pallet jack operation include falling objects (struck by hazards). Loads can fall, and operators can too. If you move a loaded pallet jack too quickly, over uneven floors, or on inclines, the load may topple. You could be injured if the load falls, and the load and/or the workplace may be damaged. Straining to move a stuck pallet jack or failing to maintain control on an incline can cause the operator to slip and fall. This lesson focuses on the safe operation of both manual and powered hydraulic pallet jacks.

Common hazards associated with pallet jack operation include falling objects (struck by hazards). Loads can fall, and operators can too. If you move a loaded pallet jack too quickly, over uneven floors, or on inclines, the load may topple. You could be injured if the load falls, and the load and/or the workplace may be damaged. Straining to move a stuck pallet jack or failing to maintain control on an incline can cause the operator to slip and fall. This lesson focuses on the safe operation of both manual and powered hydraulic pallet jacks. -

Accidents and injuries have both a human and a business cost, so it is advantageous for employees to practice safe behaviors and mitigate unsafe behaviors in the workplace. This lesson introduces behavior-based safety concepts to employees and creates awareness around what influences employees to change unsafe behaviors before an accident or injury happens.

Accidents and injuries have both a human and a business cost, so it is advantageous for employees to practice safe behaviors and mitigate unsafe behaviors in the workplace. This lesson introduces behavior-based safety concepts to employees and creates awareness around what influences employees to change unsafe behaviors before an accident or injury happens. -

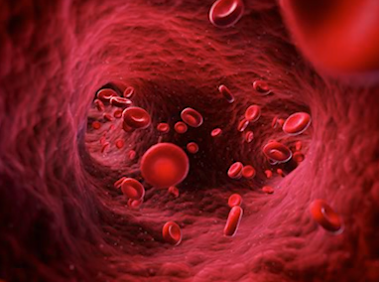

Bloodborne pathogens are viruses carried in human blood and other body fluids that cause disease in people. There are many different bloodborne pathogens, including malaria and syphilis, but the human immunodeficiency virus (HIV), hepatitis B (HBV), and hepatitis C (HCV) viruses, which can each lead to liver cancer, pose the most serious threat of workplace exposure. Perhaps no other profession is more at risk of the hazards posed by bloodborne pathogens than the medical profession, but that’s not to say that awareness and prevention measures shouldn’t be prevalent in all workplaces, because the price of ignorance can be very costly and simple understanding of some bloodborne pathogen basics, really can save lives. The goal of this training course is to educate employees to minimize their exposure to bloodborne pathogens.

Bloodborne pathogens are viruses carried in human blood and other body fluids that cause disease in people. There are many different bloodborne pathogens, including malaria and syphilis, but the human immunodeficiency virus (HIV), hepatitis B (HBV), and hepatitis C (HCV) viruses, which can each lead to liver cancer, pose the most serious threat of workplace exposure. Perhaps no other profession is more at risk of the hazards posed by bloodborne pathogens than the medical profession, but that’s not to say that awareness and prevention measures shouldn’t be prevalent in all workplaces, because the price of ignorance can be very costly and simple understanding of some bloodborne pathogen basics, really can save lives. The goal of this training course is to educate employees to minimize their exposure to bloodborne pathogens. -

This lesson covers the required awareness training on the occupational hazards common to the handling and use of chemicals, measures you can take to protect yourself from chemical hazards, safe practices for chemical storage and waste disposal, and the correct response to emergency situations involving chemical spills. This lesson does not cover information related to radiological agents, explosives, and biohazardous/infectious agents.

This lesson covers the required awareness training on the occupational hazards common to the handling and use of chemicals, measures you can take to protect yourself from chemical hazards, safe practices for chemical storage and waste disposal, and the correct response to emergency situations involving chemical spills. This lesson does not cover information related to radiological agents, explosives, and biohazardous/infectious agents. -

In order to recognize the hazards posed by compressed gas cylinders, you must first be able to recognize the specific parts of the cylinder and have a general knowledge of how these things work. Compressed gas cylinders can pose the hazard of an explosion when the metal pressure vessel fails. A common factor in that scenario is the misuse or abuse of the cylinder or valve while it is under pressure. Another hazard is the sudden release of pressure from the cylinder, as mentioned above. The purpose of this lesson is to address the hazards inherent in compressed gas and provide best practices for using, moving, and storing compressed gas containers.

In order to recognize the hazards posed by compressed gas cylinders, you must first be able to recognize the specific parts of the cylinder and have a general knowledge of how these things work. Compressed gas cylinders can pose the hazard of an explosion when the metal pressure vessel fails. A common factor in that scenario is the misuse or abuse of the cylinder or valve while it is under pressure. Another hazard is the sudden release of pressure from the cylinder, as mentioned above. The purpose of this lesson is to address the hazards inherent in compressed gas and provide best practices for using, moving, and storing compressed gas containers.