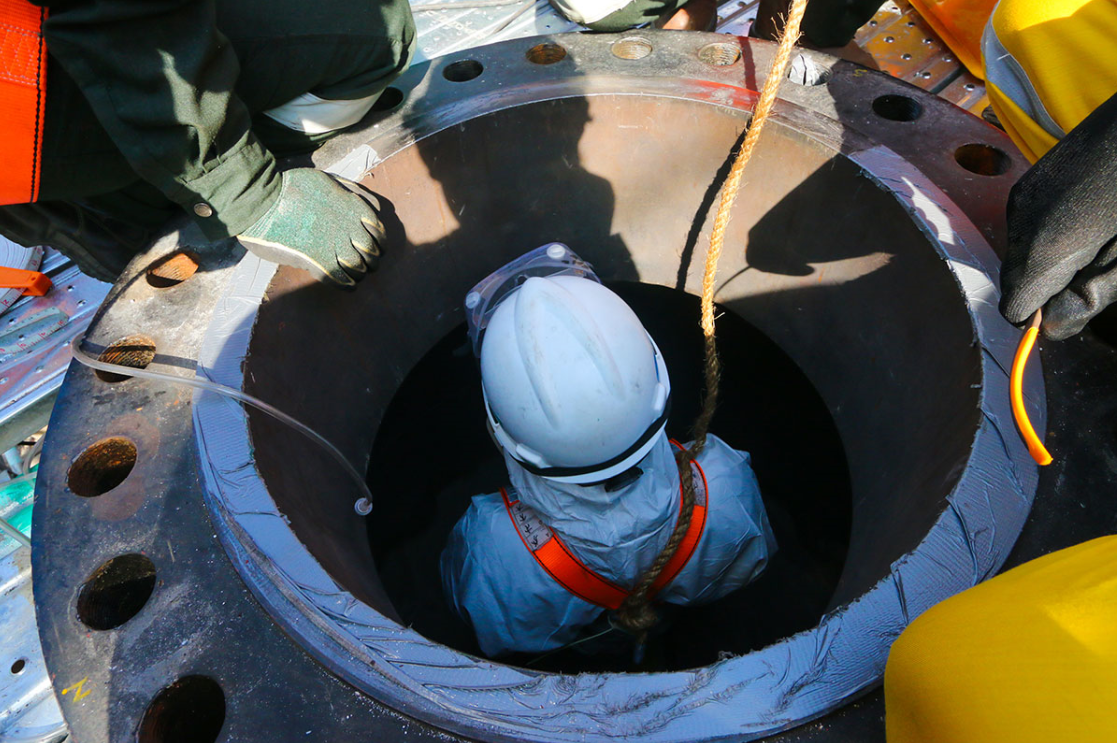

Working in a confined space is one of the most dangerous of all workplace hazards. In fact, it’s been calculated that working in a confined space is 150 times more dangerous than doing the same job outside of the space. While this Workplan is geared toward compliance remember, compliance is often only the minimum set of requirements for safety.

Step 1: Identify Permit-Required Confined Spaces

Determine if you have any confined spaces and then classify the spaces as either:

- Non-permit confined spaces – spaces that don’t contain or potentially contain hazards capable of causing death or serious harm to entrants; or

- Permit-required confined spaces – spaces that do contain actual or potential hazards capable of causing death or serious harm such as:

- Hazardous atmosphere – oxygen deficient/enriched, flammable, explosive, or fatal gases/chemical vapors

- Engulfment – potential for space to suddenly fill with liquid, sand, etc.

- Entrapment – narrow or tapering spaces, vat and bin floors that slope in and downward

Step 2: Prohibit Unauthorized Entry into Permit-Required Confined Spaces

- Secure all permit-required confined spaces:

- Secure the entrance using physical barriers, locks, warning devices or a combination to bar unauthorized entry.

- Notify workers of the existence, location and dangers of the space by posting warning signs or other effective means of communication.

- Decide how you’re going to handle the space going forward. Your options:

- Seal off the space so nobody can enter it; or

- Implement a confined spaces entry program to ensure safe entry into the space.

The rest of this Workplan covers the steps necessary to implement a confined space entry program for permit-required spaces.

Step 3: Establish Acceptable Atmospheric Conditions for Entry

Common required atmospheric conditions include:

- Oxygen levels between 19.5% and 23.5% (23% in some Canadian provinces).

- Flammable gases, vapors or mists at or below 10% of their lower flammable or lower explosive limit (LFL)/(LEL).

- Concentrations of airborne combustible dusts below their LFL.

- Concentration of substances above/potential to be above Permissible Exposure Limits (PELs).

- Any other atmospheric condition immediately dangerous to life or health (IDLH).

Step 4: Establish Atmospheric Testing Criteria

- Atmospheric testing of permit spaces is required before entry and as often as necessary during entry to verify acceptable atmospheric conditions are still present.

- Establish in the entry procedure that:

- Workers are required to evacuate the space immediately if atmospheric conditions no longer meet the specified acceptability standards.

- Re-entry is banned after evacuation until new testing verifies the atmosphere is safe.

- Testing must be carried out in the following sequence using instruments meant for testing only that condition:

- First: Oxygen

- Second: Combustible gas

- Third: Toxic gases and vapors

Use the Confined Spaces Hazard Assessment Worksheet prior to each entry and keep it at the site and in your records.

Step 5: Establish Engineering Controls for Atmospheric Hazards

A confined space entry program must list engineering controls used to manage hazardous atmospheres in the space. Acceptable methods include:

- Ventilation – mechanical systems that force fresh air into the confined space and/or exhaust contaminated air while workers are inside it.

- Purging – introducing substances such as an inert gas, steam or water into a confined space to displace or flush out contaminants before workers enter the space.

- Inerting – introducing an inert (un-reactive) gas such as nitrogen or carbon dioxide into a confined space to completely displace all oxygen.

- Isolation – disconnecting, blanking or blinding or using an equivalent engineered system to prevent a hazardous substance contained in adjacent pipelines from seeping or leaking into the permit space.

Step 6: Establish Control Methods for Physical Hazards

Protect against physical hazards by using:

- Fall protection

- Respirators/supplied air

- LOTO

- Piping isolation

- Hearing protection

- Pumps to remove water

- Barriers

- Non-sparking tools

Step 7: Establish Safe Entry and Exit Procedures

- An entry procedure must list:

- Safety measures required by regulations, e.g., hazard assessment.

- Verification of acceptable conditions of entry.

- Use of engineering controls to eliminate or control atmospheric hazards.

- Entry must be overseen by an “entry supervisor” who only allows entry after ensuring all safety measures have been carried out.

- For each entry, there must be one or more “attendants” who remain outside the space near the entrance to keep an eye on the entry, communicate with the authorized entrants inside, and provide help in case of an emergency. *No one, including attendants and entry supervisors must ever enter a confined space without specific training and protective gear.

- Entry permits must:

- Always be issued by the entry supervisor before entry and posted at the entry site whenever authorized entrants are inside the space.

- List essential information about the entry and steps taken to ensure its safety.

Step 8: Provide PPE and Safety Equipment

- Provide authorized entrants needed equipment such as respirators and hardhats, rescue or retrieval systems and gear, and communication equipment.

- Require proper inspection, use, care, maintenance and storage of PPE and safety equipment.

Step 9: Provide Rescue and Emergency Response

- Provide for rescue of authorized entrants if emergencies arise after they enter the space.

- The preferred rescue method is to use retrieval systems that make it unnecessary to send in rescue personnel.

- If rescue personnel are required, take steps to ensure rescue operations are as safe as possible.

Step 10: Conduct Training and Instruction

- A confined space entry program must provide that all personnel involved in permit-required confined space entry and rescue receive training necessary to be “proficient” before they’re allowed to carry out those duties.

- Confined spaces safety training must be provided to:

- Authorized entrants

- Attendants

- Entry supervisors

- Rescue personnel